The Story of Displays

The History of LCD

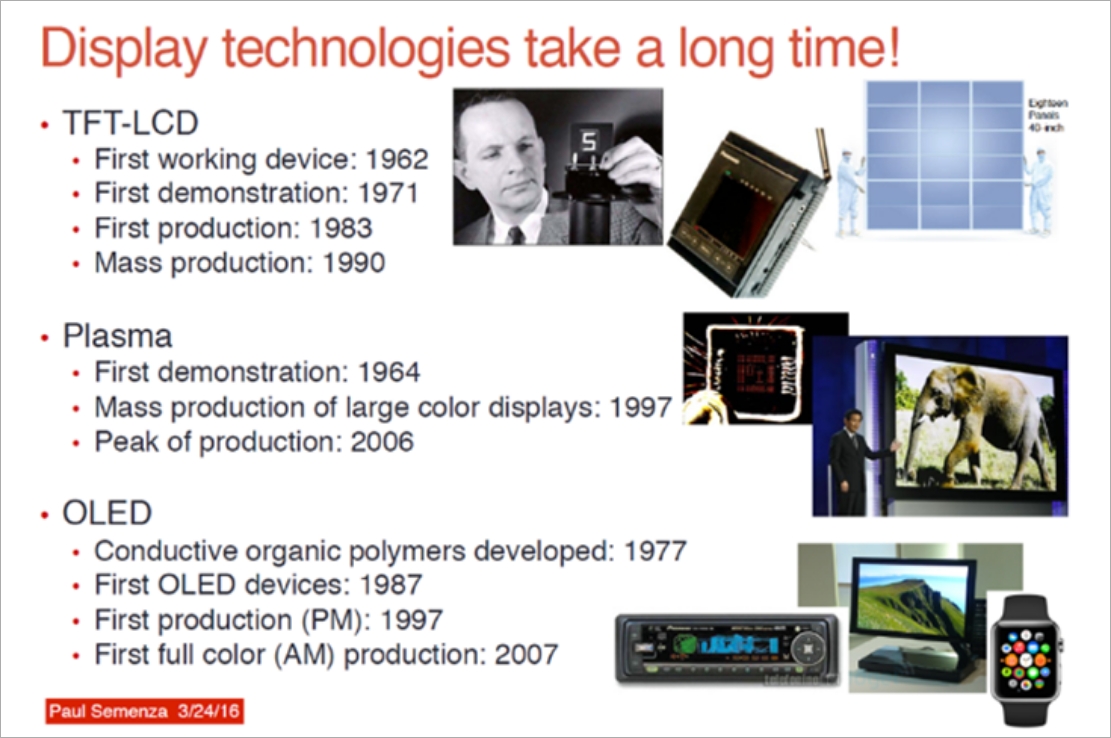

The history of LCD technology began in the late 1960s and early 1970s.

In 1968, George H. Heilmeier and other researchers initiated the development of display devices using controllable liquid crystals.

However, early LCDs had limitations such as low resolution and limited color reproduction,

which made them unsuitable for commercial applications at the time.

In the 1980s, advancements in LCD technology enabled higher-resolution displays, paving the way for adoption in computer monitors and other digital display systems.

Since the 2000s, LCDs have become a mainstream display technology.

Thanks to their low power consumption, slim form factor, lightweight design, high image quality, and wide viewing angles, LCDs are now used in a wide range of devices—from mobile phones to large-screen televisions.

Today, LCD technology continues to evolve.

The focus is on achieving higher resolution, greater contrast ratios,

faster refresh rates, and enhanced color reproduction.

Furthermore, LCDs are developing alongside and competing with new technologies such as OLED (Organic Light Emitting Diode), contributing to the ongoing evolution of the display industry.

Structure of LCD

An LCD screen consists of a thin layer of liquid crystal material sandwiched between two glass substrates, with polarizing filters placed on both sides.

These polarizers allow light waves of a specific polarization to pass while blocking others.

Images are produced by electrically controlling the orientation of the liquid crystals.

Since the electrodes must be transparent, the most commonly used material is ITO (Indium Tin Oxide).

Because LCDs do not emit light on their own, a backlight is typically placed behind the display to make it visible in dark environments.

Backlights can use either LEDs (Light Emitting Diodes) or CCFLs (Cold Cathode Fluorescent Lamps),

with LED backlighting being more efficient and widely used today.

For color displays, a color filter layer is added to the LCD cell to generate images in RGB (Red, Green, Blue).

Additionally, a touch panel can be layered on top of the LCD to enable interactivity.

The main components of liquid crystals are organic compounds.

Liquid crystals exhibit an intermediate state between liquid and solid, in which their molecules are arranged in an ordered structure.

These molecules are typically elongated and can be activated electrically or optically.

In liquid crystal displays, the orientation of liquid crystal molecules is controlled by an electric field or a light source to form images.

Thanks to this characteristic, LCDs are extremely thin, lightweight, and energy-efficient.

The specific composition of liquid crystals varies, as a wide range of compounds can be used.

The performance and properties of a liquid crystal depend on the types and combinations of compounds employed.

Common types of liquid crystals include nematic and smectic liquid crystals.

Types of LCD

[TN (Twisted Nematic) Panel]

The TN panel is another type of display panel used in computer monitors and televisions.

“TN” stands for Twisted Nematic.

TN panels are more cost-effective to manufacture compared to IPS or VA panels and offer fast response times with low input lag.

They are commonly used in gaming monitors or applications where high-speed video playback is important.

However, TN panels typically have poorer color reproduction and narrower viewing angles compared to other panel types.

[VA (Vertical Alignment) Panel]

The VA panel, short for Vertical Alignment panel, is a type of display technology used in computer monitors and televisions.

Compared to other panel types such as IPS (In-Plane Switching) and TN (Twisted Nematic), VA panels offer excellent contrast ratios and wide viewing angles, along with solid performance in color accuracy and image quality.

As a result, VA panels are commonly used for gaming, movies, and graphic design applications.

They were developed to overcome some of the shortcomings of TN and IPS panels.

Typically, VA panels feature higher contrast ratios and provide a broader range of color expression compared to IPS panels.

[IPS (In-Plane Switching) Panel]

The IPS panel, short for In-Plane Switching, is another type of display technology used in computer monitors and televisions.

IPS panels offer wide viewing angles and excellent color accuracy, maintaining high image quality by minimizing shadowing and color distortion.

They provide more consistent color reproduction than VA panels and are ideal for tasks that require color precision,

such as graphic design, photo editing, video production, and general use.

However, some IPS panels may have slower response times and typically offer lower contrast ratios compared to VA panels.

Difference Between LCD Panels

and Newer Display Technologies

Until recently, most displays used TN, IPS, or VA panels—each based on LCD (Liquid Crystal Display) technology with their own strengths and weaknesses.

However, newer panel technologies such as OLED, QLED, and Micro LED have emerged, signaling a shift in the display industry.

While traditional LCD-based panels (TN, IPS, VA) are still commonly used in most computer monitors,

newer technologies like OLED and QLED are gradually gaining ground, particularly in other types of devices.

In the case of laptops, where display sizes typically range from 13 to 17 inches, OLED technology is becoming more prevalent.

Because OLED pixels emit their own light, they can offer higher contrast ratios and more vivid colors making them

ideal for smaller screens that benefit from rich, high-quality visuals.

That said, due to the high cost of OLED technology, many mainstream laptops still do not adopt OLED panels.

Instead, IPS, VA, and TN panels remain the most commonly used technologies,

and they too are capable of delivering excellent image quality for everyday use.